The Burj Khalifa in Dubai, UAE, the tallest building in the world at 828 meters high, has a structure of reinforced concrete.

The Burj Khalifa in Dubai, UAE, the tallest building in the world at 828 meters high, has a structure of reinforced concrete.

The cornerstone of the global construction industry is, for better and worse, concrete. Builders ancient and modern have been drawn to the material’s durability, versatility, and efficiency, but its benefits come at an environmental cost. Researchers today are finding new ways to improve concrete’s performance and mitigate its expense.

Mukhtar Ibrahim, Head of Structural Department

Ahmad kadri, Senior Structural Engineer

Innovations in concrete production have long driven innovations in architecture. The mixture of coarse aggregate, cement, and water is the most widely used building material in the world, and one of the oldest. Although it is commonly believed that ancient Romans were the first to use concrete, beginning in 300 BCE, recent research has traced the use of concrete-like materials much farther back. Ancient Greek, Egyptian, and Chinese builders mixed lime concrete over 4,000 years ago, and lime concrete floors have been discovered in 10,000-year-old agricultural settlements in the Middle East, corresponding to the Agricultural Revolution. Still, no ancient civilization is more associated with concrete than the Roman Empire — no doubt thanks to the great temples, basilicas, bathhouses, and infrastructural wonders that still awe and inspire us. The ancient Roman architect Vitruvius described the wonders of concrete, called pozzolana, in the oldest surviving written work on building, The Ten Books on Architecture:

There is also a kind of powder which from natural causes produces astonishing results. It is found… in the country belonging to the towns around about Mt. Vesuvius. The substance, when mixed with lime and rubble, not only lends strength to building of other kinds, but even when piers of it are constructed in the sea, they set hard under water…..When the three substances…are mixed together, the water suddenly taken in makes them cohere, and the moisture quickly harness them so that they set into a mass which neither the waves nor the force of the water can dissolve.

The ancient dome of the Pantheon in Rome was built of concrete that is similar to modern concrete, but without rebar. Photo © Yuri Turkov

The Pantheon in Rome (113-125 CE) is perhaps the most celebrated of these ancient concrete structures. Its dome, 43 meters in diameter, was built using materials whose composition is strikingly similar to modern concrete, though lacking the steel reinforcement that is conventional today. The fact that it still stands today is a testament to the material’s durability.

Unfortunately, after the fall of the Roman Empire, the recipe for concrete was lost for centuries. One of the first modern uses of concrete was undertaken in the eighteenth century by engineer John Smeaton who, in 1759, built a new lighthouse on a particularly tumultuous patch of sea off the coast in England, binding its stones with a mixture of quicklime, clay, sand, and crushed iron-slag. Smeaton’s success with the Eddystone Lighthouse motivated others to explore the materials, and the first standardized formula for hydraulic cement (cement that hardens in water) was patented in 1824 by English inventor Joseph Aspdin under the name “Portland Cement.”

The next major innovation in concrete was steel reinforcing. Credit for this advancement is given to French gardener Joseph Monier who, in 1849, frustrated by the fragile concrete planters that were popular in the mid-nineteenth century, began experimenting with pouring concrete over steel mesh. His idea may have been inspired by methods of interlacing wires into plaster, as famously used by architect Henri Labrouste in the vault of the Sainte-GenevieveLibrary (1843-51) in Paris. Whatever his inspiration, the idea worked. Reinforced concrete, also known as ferroconcrete, combines the best qualities of two materials: the flexibility of concrete and the strength of steel. Monier exhibited his pots for the first time at the Paris International Exhibition in 1867, but soon realized his invention could be used for much more and quickly patented designs for concrete pipes, architectural concrete panels, and concrete bridges.

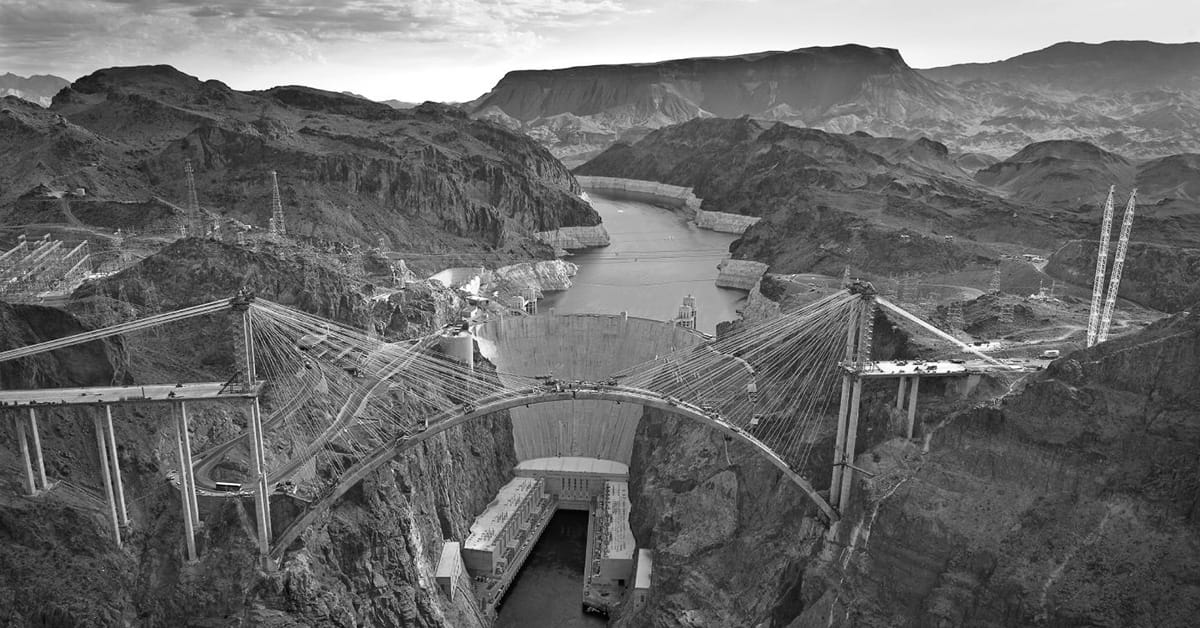

The Hoover Dam on the Colorado River, USA, is a traditional gravity dam built with the latest concrete construction technology of the 1930s. It consists of 2.5 million cubic meters of poured reinforced concrete, poured into individual box molds to facilitate curing.

Soon after Monier patented his reinforced concrete technique, others began improving it. In 1886 American engineer PH Jackson patented prestressed concrete, which is placed under compression prior to its installation to counteracts the stresses that occur when additional building loads are added; stresses are thus carried by the entire structural element rather than just the steel reinforcing, increasing resistance to shock and vibration.

With developments happening so rapidly, this new material was quickly employed for architectural purposes. A generation of experimental architects felt emboldened by the possibilities of concrete and, perhaps ironically, saw it as a means to break from history and tradition. As Giedion notes, “between 1910 and 1920 it became almost the trademark” of the modern movement in architecture. By the 1950s-70s, reinforced concrete architecture took on increasingly expressive forms in the hands of architects and engineers such as Pier Luigi Nervi, Eero Saarinen, and Jørn Utzon, to name just a few.

Eero Saarinen, TWA Flight Center, JFK Airport, New York, USA, 1956-62. Saarinen achieved expressive plasticity using reinforced concrete. Photo © Eric Saarinen, ASC / Peter Rosen Productions, Inc.

Today, concrete is used to build simple utilitarian structures, looming monoliths and monuments, and breathtaking sculptural icons. It’s used in buildings, bridges, streets, and sidewalks. It still has a weight and sense of permanence that make it both beloved and despised. It can be brutal. It can be elegant. It’s flexibility is surpassed only by its ubiquity.

However, a persistent downside to concrete is the amount of energy and effort expended to extract, manufacture, and transport it. Additionally, if mixed or installed incorrectly, the stability of the material can be undermined. New research and emerging technologies aim to rectify these issues. As we detailed in a recent post, researchers around the world are improving the performance of concrete by making it more efficient, more durable, and perhaps most amazing of all, translucent. It’s also being used in early experiments in architectural “3D printing.”

We’re still discovering what concrete can do. Although it’s not without its downsides, concrete’s sheer versatility, combined with new technologies and a growing awareness of the environmental factors, promise the material will continue to shape our great monuments and infrastructural wonders.

Of the many historic milestones in the development of concrete as a modern global building material, here are a few of our favorites:

- 1886: The first rotary kiln is introduced in England that made constant production of cement.

- 1891: George Bartholemew paves the first concrete street in the USA in Bellefontaine, Ohio.

- 1903: The first reinforced concrete high-rise structure, the 16-story Ingalls Building, is built in Cincinnati, Ohio, USA, designed by Elzner & Anderson.

- 1930: Air entraining agents are introduced to concrete to improve resistance to freeze/thaw damage.

- 1935: The Hoover Dam is completed after pouring 2.5 million cubic meters of concrete

- 1970s: fiber reinforcement is introduced to concrete

- 1980s: superplasticizers are introduced as admixtures to enhance workability; silica fume pozzolanic powder is introduced to add strength and reduce permeability.

- 1989: The 58-story, 720 foot Two Union Square tower in Seattle demonstrates “highest strength” structural concrete with a target compressive strength of 19,000 psi.

- 1990: Chicago’s 65-story tower at 311 South Wacker Drive becomes the tallest reinforced concrete building in the world at 293 meters high.

- 1999: Polished concrete by HTC, a Swedish company, is used in a 4,000-square-meter application at the Bellagio Hotel in Las Vegas

- 2008: The Burj Khalifa in Dubai, UAE becomes tallest reinforced concrete building in the world, rising 828 meters high. Built 2004-2009, it incorporates 330,000 cubic meters of concrete reinforced by over 55,000 tonnes of rebar.