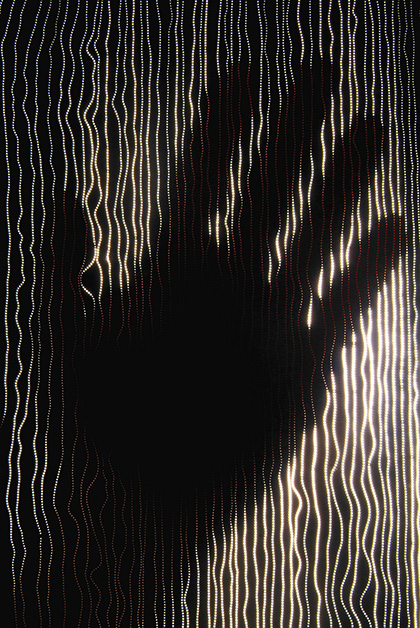

Lunacrete translucent concrete. Photo © SOLI Architectural Surfaces

Lunacrete translucent concrete. Photo © SOLI Architectural Surfaces .

Scientists and researchers are developing ways to make concrete — the most widely used building material in the world — more efficient, which could transform the building industry in Saudi Arabia and around the world.

By Mukhtar Ibrahim, Head of Structural Department

and Ahmed Alkadri, Senior Structural Engineer

There’s a long history of concrete construction in Saudi Arabia, where the abundance of natural resources such as sand, clay, and limestone — the primary materials used to make cement and concrete — has made the building material nearly ubiquitous, as has the availability of petroleum required to effectively manufacture it. Saudi Arabia is one of the largest producers of the concrete in the world and, with infrastructure and architecture projects underway across the country, it is also becoming one of the largest consumers. There are many benefits to concrete construction, but demands for increased sustainability and longevity are driving a new wave of innovation in concrete technology.

One of the newest developments in materials research is “self-healing” concrete. Although concrete is an incredibly durable material, it is prone to cracking in response to changes in thermal conditions or shifting environmental conditions — especially if it’s not mixed or installed properly. To combat cracking, a research team at Delft Technical University developed “self-healing” concrete in 2012 by introducing a limestone-producing bacteria into the aggregate. The bacteria, along with its required nutrients, are added to the concrete mix during production. When water infiltrates the concrete through micro-fractures, the bacteria is activated to fill those fractures.

Other research teams have since taken up the project, developing various types of self-healing concrete using both organic and inorganic compounds. While the material would certainly be useful for creating more durable buildings, it may have even greater benefits for infrastructure, producing bridges, roadways, and other structures that can “continually monitor, regulate, adapt, and repair themselves without the need for human intervention,”according to a professor at Cardiff University’s School of Engineering.

At Rice University in Houston, Texas, researchers are working on a material they call “programmable cement,” which is likewise designed to increase the durability and longevity of cement and concrete. Although it’s not as digital as its name implies, programmable cement is no less impressive. Essentially, researchers are able to shape the material’s microscopic particles into regimented forms rather than the disordered clumps that normally comprise cement. The resulting material is denser, stronger, more resistant to corrosion and infiltration, and potentially more versatile than traditional cement. As a result, it’s also more environmentally friendly because less would be needed.

Perhaps the most radical recent development is transparent concrete, currently marketed as LitraCon, which introduces tiny optical fibers into the aggregate that comprises the concrete. The resulting material is a translucent block that lies somewhere between glass and concrete. It has a homogenous inner structure and surface, and can be used to build very thick walls, as the light can be transmitted up to 20 meters through concrete with no loss of brightness.

As the most used building material, concrete is also the most intensively researched. Its potentials as a building material are still being discovered, allowing for new possibilities even after millennia of intermittent use. These most recent developments might seem like something from a science-fiction future, but they have all already been used in small construction projects and prototypes. Soon these emerging materials may be used to shape streets,buildings, and cities around the world.